1. What is Stone Paper?

Stone paper is made of limestone mineral resources with large reserves and wide distribution as the main raw material (calcium carbonate content is 70-80%) and polymer as auxiliary material (content is 20-30%). By using the principle of polymer interface chemistry and the characteristics of polymer modification, stone paper is made by polymer extrusion and blowing technology after special processing. Stone paper products have the same writing performance and printing effect as plant fiber paper. At the same time, it has the core properties of plastic packaging.

2. The key features of stone paper?

The stone paper properties including the safety, physical, and other features, and main features is waterproof, prevent mist, prevent oil, insects, etc., and on the physical properties the tearing resistance, folding resistance are better than wood pulp paper.

The stone paper printing will not be etched with higher definition, up to 2880DPI accuracy, the surface is not covered with film, will not have chemical action with ink, which will avoid color cast or decolorization phenomenon.

3. Why do we choose stone paper?

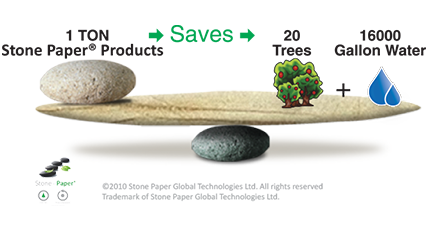

a. Raw material advantage. Traditional paper to consume a lot of wood, and stone paper is the most abundant mineral resources in the earth’s crust calcium carbonate as the main raw material, about 80%, polymer material – a petrochemical production of polyethylene (PE) about 20%. If plan an annual output of 5400kt stone paper, 8.64 million m3 wood can be saved every year, equivalent to reducing deforestation of 1010 square kilometers. According to the traditional process of water consumption of 200t per ton of paper, the annual output of 5.4 million tons of stone paper project can save 1.08 million tons of water resources every year.

b. Environmental advantages. The whole production process of stone papermaking does not need water, compared with the traditional papermaking it deletes cooking, washing, bleaching and other pollution steps, fundamentally solve the traditional papermaking industry waste. At the same time, the recycled stone paper is sent to the incinerator for incineration, which will not produce black smoke, and the remaining inorganic mineral powder can be returned to the earth and nature.

Stone papermaking greatly saves forest resources and water resources, and the unit energy consumption is only 2/3 of the traditional papermaking process.

Post time: May-13-2022