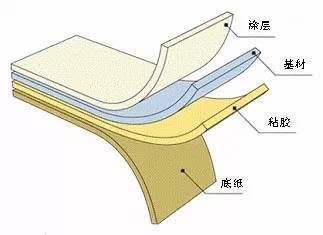

The structure of self-adhesive label is composed of three parts, surface material, adhesive and base paper. However, from the perspective of manufacturing process and quality assurance, self-adhesive material consists of seven parts below.

1、Back coating or imprint

Back coating is a protective coating on the back of the backing paper, to prevent waste, the adhesive around the label after rewinding is stuck to the paper. Another function is to make multilayer labels. Back printing function is to print the manufacturer’s registered trademark or pattern on the back of the backing paper, playing the role of publicity and anti-counterfeiting.

2、Surface coating

Used to change the surface properties of the surface material. Such as improving the surface tension, changing the color, increasing the protective layer, so that it better accept ink and easy to print, to prevent dirt, increase the adhesion of ink and prevent the purpose of printing words and texts off. Surface coating is mainly used for non-absorbent materials, such as aluminum foil, aluminized paper and various film materials.

3、Surface materiel

That is, the surface material, is the front side receives the printed text, the back side receives the adhesive and is finally applied to the paste on the material.Generally speaking, all flexible deformation materials can be used as the fabric of self-adhesive materials, such as common paper, film, composite foil, all kinds of textiles, thin metal sheets and rubber.

The type of finish depends on the final application and printing process. The surface material should be suitable for printing and printing, have good inking properties, and have sufficient strength to accept various processing, such as die cutting, waste discharge, slitting, drilling and labeling.

4、Binding agent

The binding agent is the medium between the label material and the bonding base material. According to its characteristics can be divided into permanent and removable type. It has a variety of formulations, suitable for different toppings and different occasions. The binding agent is the most important component of self-adhesive material technology and the key of label application technology.

5、Release coating

Release coating (coating silicon layer) that is, coating silicone oil layer on the surface of the base paper. Cloth silicone oil can make the base paper into a very low surface tension, very smooth surface, the role is to prevent adhesive bonding on the base paper.

6、Backing paper

The function of the base paper is to accept the release agent coating, protect the adhesive on the back of the surface material, and support the surface material, so that it can be die-cutting, waste discharge and labeling on the labeling machine.

7、Undercoat

It is the same as the surface coating, but is coated on the back of the surface material, the main purpose of the bottom coating is:

a. Protect the surface material to prevent the penetration of adhesive.

b. Increase the opacity of fabric

c. Increase the bonding force between adhesive and surface material

d. Prevent the plasticizer in the plastic surface from infiltrating into the adhesive, affecting the performance of the adhesive, reducing the bonding force of the label, and causing the label to fall off.

Post time: Apr-16-2022