After 40 years of development, China has become the world’s largest producer and consumer in label industry. The annual consumption of labels is about 16 billion square meters, about a quarter of the total global label consumption. Among them, the consumption of self-adhesive labels accounts for more than one third of the total consumption of labels in China, namely 6 billion to 7 billion square meters, and the rest are paper labels, shrink-film labels, in-mould labels and sleeve labels

Chinese label printing, especially self-adhesive label printing, is greatly influenced by Japan. At present, letterpress printing accounts for about 60%, is still the mainstay of label printing industry; Off set printing accounts for about 20% and is the fastest growing printing way; Flexography printing accounts for about 10%, is the most ideal way of printing, but affected by a variety of factors in China, is currently installed in large quantities, small boot. The other 10% is digital printing and other printing methods such as screen printing, gravure printing and special printing

Digital printing is the fastest developing technology in the field of label printing. Usually, digital printing uses inkjet, toner, electronic ink and inkjet transfer methods.

The most striking is composite printing, which combines digital printing with traditional printing.

Seven-color printing, also known as “high-fidelity printing”, expands the color gamut and greatly improves the color quality of printed matter. Using dot overlay printing field instead of special color ink printing field, no need to configure special color ink, reduce material consumption and cost; When a printer prints multiple orders, it only needs to change the plate without cleaning the cots and changing the ink, which improves the production efficiency.

It uses low transfer ink, applied in roller ink transfer equipment, ink viscosity and print color difference can be randomly adjusted, print color consistent, high printing efficiency, is 2 ~ 3 times of traditional label printing equipment.

Flexography is a type of printing that uses flexo plates and transfers ink through a anilox roller. Flexographic printing plate generally uses the thickness of 1-5mm photosensitive resin plate. Ink is divided into three categories, respectively water-based ink, alcohol-soluble ink, UV ink. As flexographic printing ink is green, it has been widely used in food packaging printing and has broad prospects.

PS plate printing self-adhesive label is with low cost of offset plate making and good printing effect, offset label machine is the first choice of label printing enterprises in addition to the traditional letterpress machine. Offset printing makes up for the defects of letterpress graphics, plate making cost is low, suitable for all kinds of orders, welcomed by label printing enterprises.

The biggest characteristic of letterpress is short, flat, fast, printing enterprises can make their own plate, printing ink, good shelf effect, simple operation, easy to adjust, suitable for all kinds of middle label products.

Letterpress machine is mainly divided into two categories: one is half rotary letterpress machine, commonly known as letterpress intermittent machine; The other is full rotary letterpress. Although letterpress label printing have not been seen in the top label printing enterprises in China, It’s still the main force of self-adhesive label printing in small and medium-sized label printing enterprises, accounting for about 60%, and this situation will not change in the short term.

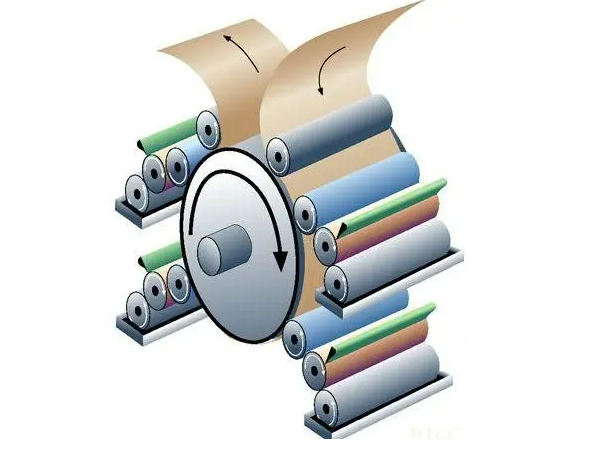

Combination printing is to achieve several different printing methods on a single device, which can be generally achieved on flexography printing machines,

Traditional combination printing is usually based on flexography printing combination, if necessary, add cold stamping, screen printing, one step to complete the printing. Combined printing in the modern sense is the combination of digital printing with traditional printing, that is, a label has both traditional printing and digital printing with variable content, forming a dynamic variable data printing production line.

The development direction of printing technology is digitalization, and digitalization starts from pre-press. The label industry has basically realized CTP plate making in flexography and offset printing, but the penetration rate of CTP plate making in letterpress is only about 10%, and China’s label industry is mainly letterpress, so CTP plate making has a huge potential market in the label industry.

In-mold label is one of the fastest developing products in the label industry chain at home and abroad. It has a history of nearly 30 years in China. It has two characteristics: first, it has good decorative effect and is the caviar to the general in the label family; Second, because there is no base paper, only a layer of film, the label can be recycled with the container, so the environmental protection characteristics are good. In-mold label is also a decoration method recommended by the international packaging and printing industry. It is divided into two categories: blow molding and injection molding.

Post time: Apr-08-2022